established 1925 - culture of craft

Wood

Rain showers Struer this morning. A biting chill hangs over the small town. But in the wood workshop, known simply as No. 22, the day has already begun. Step inside.

Step 1

Raw materials

Here, among the hum of saws and the sweet scent of sawdust, the first cuts are made. Inside, the air feels different. Dry and crisp. Carefully calibrated. Rows of timber line the walls and shelves. European oak and ash. American walnut.

Bolivian rosewood and teak from Panama. Each piece chosen for its beauty and strength.

Each piece sourced from long-time partners ike Davinde Sawmill, a local supplier. Once, a sycamore from the gardens of Versailles came to No. 22 through Davinde.

A tree that had lived through the height of French monarchy – and through its fall. Now, it lives on as one-off works of art. One of many stories, but this is where that process begins.

Next, we’ll talk about how it takes shape.

Step 2

Processing

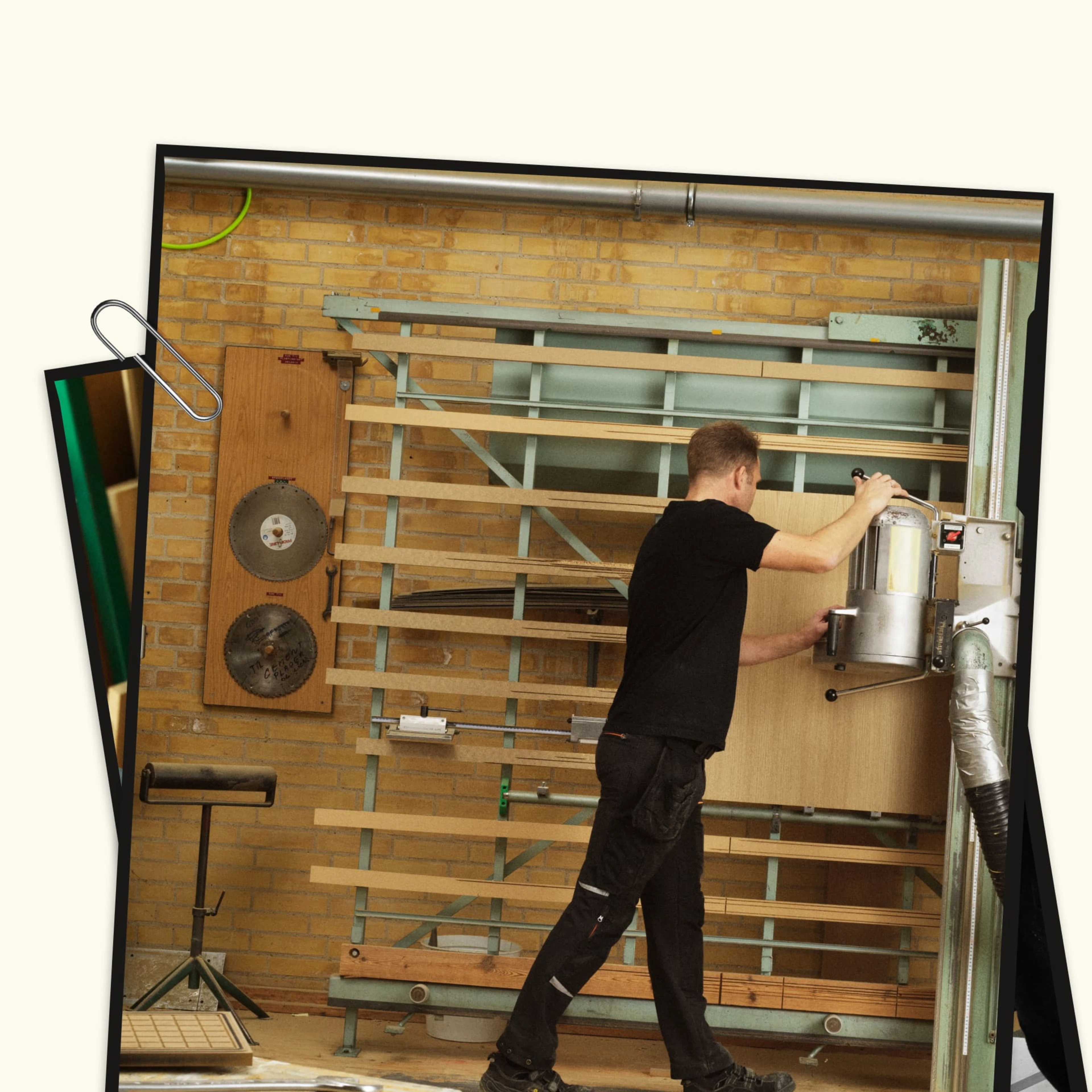

There’s no production in this workshop. Only creation. Prototypes, bespoke commissions and even store designs. Every plank, slab and beam is chosen for its purpose. Long, delicate lamellas? A good fit for hard woods like oak and walnut. Soft, flexible curves? More elastic woods like ash or beech do nicely.

The wood is then cut down to size and shaped.

The wood is then cut down to size and shaped. At the centre of the room sits a vast, futuristic-looking machine. It’s a CNC unit that shapes wood with impossible precision. These things make airplane parts. But even a machine like this will only go so far, and experienced hands take it from here.

A steady rhythm of shaving, sanding and aligning follows. Calloused fingers constantly sweep in to judge the smoothness. Soon, this piece of wood will find its new form. But before it does, it needs oil.

Step 3

Oiling

Oiling is where the wood truly comes alive. A piece of European oak drinks deeply, revealing a honey-like glow as the grain leaps into focus. Each piece is treated by hand – with sponge and cotton cloth. But sometimes the precision of a machine is needed.

This step is more than surface deep. Oiling preserves the wood.

Protects it from grease and stains while breathing new life into pattern. Sometimes, the project needs a natural and oiled finish. Other times, it needs lacquer. Or paint. Or staining. The treatment doesn’t have to stop here, but it always starts here. In many ways it’s a simple, ancient process – but one honed and taken to new places over many years.

Step 4

Quality assurance

Quality inspection isn’t an afterthought – it’s embedded in every step. From selection to shaping, from sanding to oiling, the team’s experienced hands and eyes monitor the wood constantly.

Checking pattern and knots. Bends and angles. Watching for rising grain and feeling for imperfections. How it bends – or how it doesn’t.

This diligence ensures each piece of work leaving No. 22 meets more than technical standards. It must pass the ultimate test: human appreciation. No machine understands aesthetics or design goals the way craftspeople do. There is no threshold here. The grain must flow just right, the surface smooth to the touch. And then, when every detail eventually meets these self-imposed high standards, the wood moves forward.

Meet Søren, our master wood worker

Søren Astrup has been with Bang & Olufsen for ten years now, but his fascination with wood began much earlier. “When I was maybe eight, my parents gave me a gift: a pile of planks, a hammer, a saw and some nails. A couple of days later, I’d worked my way through and was itching for more,” he says, laughing.

Asked if there’s a particular moment during his time with B&O that stands out, Søren takes a moment to think. He brushes some sawdust from his pants.“When we got our CNC machine,” he says, walking towards the room where the futuristic-looking saw lives. It’s the size of a small shed. The large touch-screen promises a steep learning curve. “I had to do a week of training to even be able to use it. It has five axes, which basically means it lets us shape wood in ways we’d never imagined before,” Søren says.

Now, as workshop manager, he oversees the wood projects that come through No. 22 – and the craft that goes out. No small task: this place is as much a lab as a workshop. Drying his hands with a towel, he says “I feel very privileged. I get to experiment with techniques and wood types. Me and the team spend our days coming up with new approaches to a very old trade.”

“I make beautiful things out of beautiful things. You don’t work wood, you work with it. And when that relationship works out, it’s magic.”

Our selection

Related stories

Join the House of Bang & Olufsen

Be the first to enjoy new and limited products, exclusive events, special offers and much more.